The 180°bends is made of 304 stainless steel pipe. Each bend is individually bent and the ends are laser cut. The bends were then finely sanded with 180-grit sandpaper and ultrasonically cleaned.

The stainless steel 180° long radius to bends has a good U-shaped curve and is suitable for piping systems where reverse flow or a complete change of flow direction is required. The key to this style of pipe bend is that each end of the bend is round and precise so that the extended leg can maintain its original roundness.

The bend radius of the 180° long radius elbow is large, generally 1.5 or 2 times the pipe diameter. Long-radius bends take up more space than short-radius bends, and their curvature is more gentle.

180° stainless steel long-radius tube bends are also considered special-shaped tubes. Stainless steel profiled pipes are widely used in various structural components, tools, machine parts, etc.

Stainless steel profile pipes generally have a larger moment of inertia and section modulus than round pipes, and have better resistance to bending and twisting, which can significantly reduce the weight of structures and save steel.

At the same time, due to the corrosion resistance, oxidation resistance, acid resistance, and alkali resistance of stainless steel, these pipe fittings are widely used in various industrial environments to change the flow direction and angle of pipelines. A long radius gives less frictional resistance. Fully Hygienic, Polished and Descaled for that distinctive look that hides fingerprints.

Introduction

|

180° Long Radius Tube Bends |

|

|

Item |

Stainless Steel 180°Long Radius Tube Bends |

|

Standard |

SMS, DIN, 3A, or According to customer requirement |

|

Material |

Stainless steel 304 or 316 |

|

Surface |

mirror polished |

|

Type |

ERW |

|

size |

NPS 0.5"-24" |

|

Delivery time |

Within 5-30 days after receiving the prepaid |

|

Packing |

Plastic Bag, Plywood Case |

|

Application |

Pipe Lines Connect |

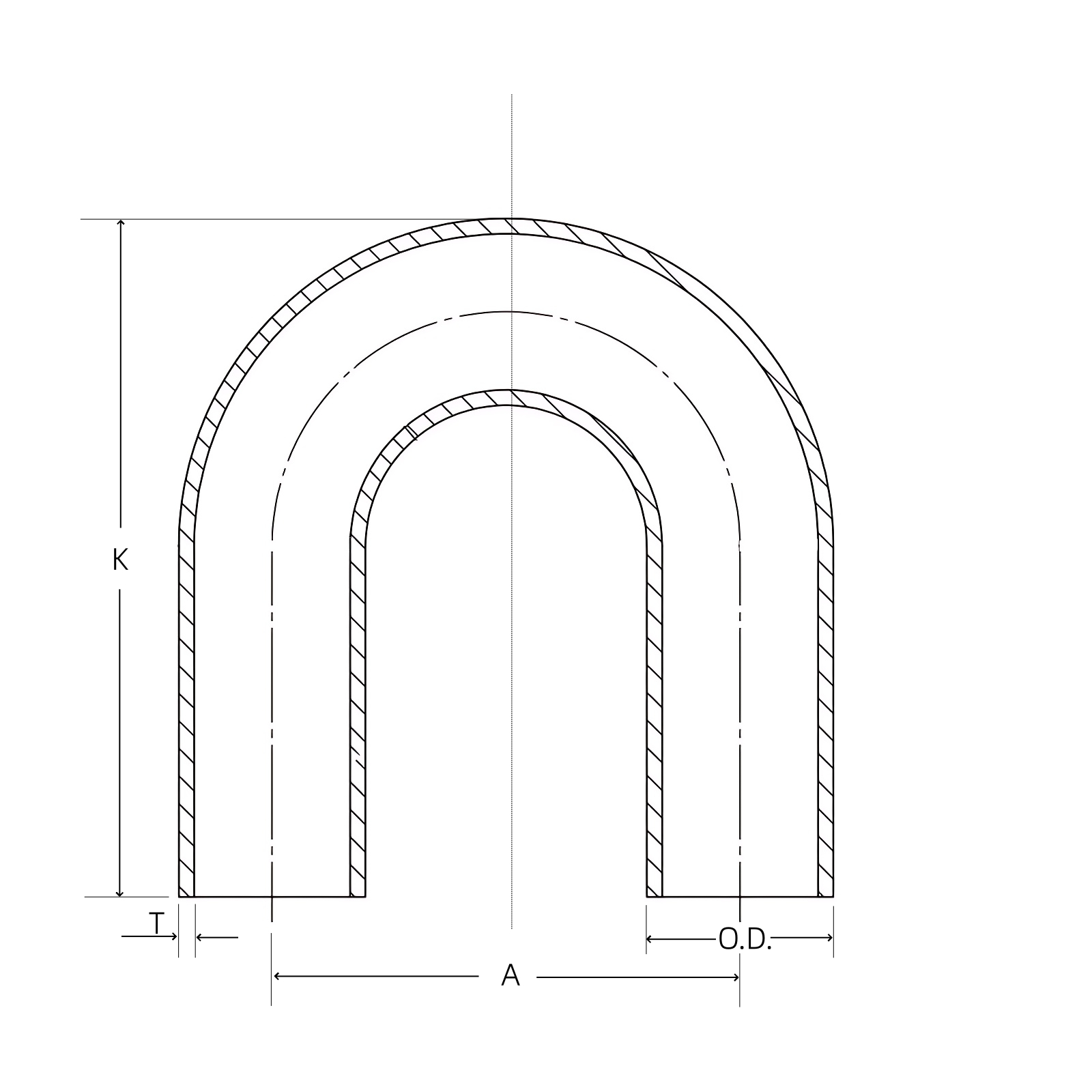

Unit:mm

|

Nominal Pipe Size |

Outside Diameter at Bevel |

Center to Center |

Back to Face |

Wall Thickness |

|

NPS |

O.D. |

A |

K |

T |

|

0.5" |

21.3 |

76.2 |

47.8 |

2.8 |

|

0.75" |

26.7 |

76.2 |

50.8 |

2.9 |

|

1" |

33.4 |

76.2 |

55.6 |

3.4 |

|

1.25" |

42.2 |

95.2 |

69.8 |

3.6 |

|

1.5 |

48.3 |

114.3 |

82.6 |

3.7 |

|

2" |

60.3 |

152.4 |

106.4 |

3.9 |

|

2.5" |

73.0 |

109.3 |

131.8 |

5.2 |

|

3" |

88.9 |

228.6 |

158.8 |

5.5 |

|

3.5" |

101.6 |

266.7 |

184.2 |

5.7 |

|

4" |

114.3 |

304.8 |

209.6 |

6.0 |

|

5" |

141.3 |

381.0 |

261.9 |

6.6 |

|

6" |

168.3 |

457.2 |

312.7 |

7.1 |

|

8" |

219.1 |

609.6 |

414.3 |

8.2 |

|

10" |

273.1 |

762.0 |

517.7 |

9.3 |

|

12" |

323.9 |

914.4 |

619.3 |

9.5 |

|

14" |

355.6 |

1066.8 |

711.2 |

9.5 |

|

16" |

406.4 |

1219.2 |

812.8 |

9.5 |

|

18" |

457.2 |

1371.6 |

914.4 |

9.5 |

|

20" |

508.0 |

1524.0 |

1016.0 |

9.5 |

|

22" |

558.8 |

1676.4 |

1117.6 |

9.5 |

|

24" |

609.6 |

1828.8 |

1219.2 |

9.5 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Thick Wall 180 Degree Stainless Steel Mandrel Bend Long Legs suppliers and OEM/ODM Thick Wall 180 Degree Stainless Steel Mandrel Bend Long Legs manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Bottom line: how to weld stainless steel pipe without sugar and leaks For most stainless steel pipe work, the most reliable path to clean, corrosion-resistant, leak-tight welds is: GTAW (TIG) root wi...

View MoreDirect answer: what a “stainless steel pipe pressure rating” really means A stainless steel pipe does not have one universal pressure rating. The correct “stainless steel pipe pressure rating” is the...

View MoreIn our shop, bending stainless steel pipe is one of those operations that looks simple but punishes shortcuts. Stainless work-hardens, it springs back, and thin-wall sections will oval or wrinkle if t...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.