Lap Joint Flange does not have a raised face, it is used in conjunction with a “Lap Joint Stub End”- a lap joint stub end and a lap joint flange. The use of it at points where severe bending stress occurs should be avoided.

Since the lap joint flange itself is not welded to the pipe, it may rotate to align bolt holes readily and the assembly and disassembly are much easier. This feature simplifies installation, maintenance, and repair tasks, reducing downtime and overall costs. The design of the flange allows for angular misalignment of pipes, ensuring a tight and leak-proof joint even when pipes are not perfectly aligned.

The crevices formed between the internal surface of the flange bore and the external surface of the stub ends may collect contaminates readily. The collected contaminates could present a problem and result in crevice corrosion.

They are usually used in low-pressure applications, such as petrochemicals, oil and gas, water treatment, food and beverage, and chemical processing industries.

Introduction

|

Standard |

ANSI/ASME : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 |

|

Material |

Carbon steel: ASTM A105, A350 LF2 |

|

Surface |

polished, Shot blasting, Sandblasting, etc |

|

Type |

Forged, Heat-treated and machined |

|

size |

1/2'' to 48" |

|

Delivery time |

Within 5-30 days after receiving the prepaid |

|

Packing |

Standard export wooden case or as you requested |

|

Application |

petrochemical, oil and gas, water treatment, food and beverage, and chemical processing industries, etc. |

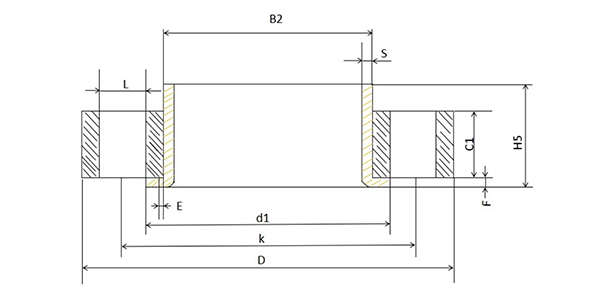

PN10

|

DN |

Pipe OD |

D |

B2 |

C1 |

K |

E |

L |

Qtty. |

Weight |

|

200 |

2198.1 |

340 |

226 |

24 |

295 |

6 |

22 |

8 |

8.87 |

|

|

204.0 - 206.0 |

340 |

213 |

24 |

295 |

6 |

22 |

8 |

8.87 |

|

250 |

273.0 |

395 |

281 |

26 |

350 |

8 |

22 |

12 |

11.20 |

|

|

254.0 - 256.0 |

395 |

264 |

26 |

350 |

8 |

22 |

12 |

11.20 |

|

300 |

323.9 |

445 |

333 |

26 |

400 |

8 |

22 |

12 |

12.80 |

|

|

304.0 - 306.0 |

445 |

315 |

26 |

400 |

8 |

22 |

12 |

12.80 |

|

350 |

355.6 |

505 |

365 |

30 |

460 |

8 |

22 |

16 |

19.40 |

|

400 |

406.4 |

565 |

416 |

32 |

515 |

8 |

26 |

16 |

26.40 |

|

450 |

457.0 |

615 |

467 |

36 |

565 |

8 |

26 |

20 |

32.20 |

|

500 |

508.0 |

670 |

519 |

38 |

620 |

8 |

26 |

20 |

38.50 |

|

600 |

610.0 |

780 |

622 |

42 |

725 |

8 |

30 |

20 |

52.20 |

PN16

|

DN |

Pipe OD |

D |

B2 |

C1 |

K |

E |

L |

Qtty. |

Weight |

|

50 |

60.3 |

165 |

65 |

20 |

125 |

5 |

18 |

4 |

2.52 |

|

|

53.0 - 54.0 |

165 |

65 |

20 |

125 |

5 |

18 |

4 |

2.52 |

|

65 |

76.1 |

185 |

81 |

20 |

145 |

6 |

18 |

8 |

3.05 |

|

|

68.0 - 70.0 |

185 |

75 |

20 |

145 |

6 |

18 |

8 |

3.05 |

|

80 |

88.9 |

200 |

94 |

20 |

160 |

6 |

18 |

8 |

3.48 |

|

|

83.0 - 84.0 |

200 |

89 |

20 |

160 |

6 |

18 |

8 |

3.48 |

|

100 |

114.3 |

220 |

120 |

22 |

180 |

6 |

18 |

8 |

4.20 |

|

|

103.0 - 106.0 |

220 |

113 |

22 |

180 |

6 |

18 |

8 |

4.20 |

|

125 |

139.7 |

250 |

145 |

22 |

210 |

6 |

18 |

8 |

5.21 |

|

|

128.0 - 133.0 |

250 |

138 |

22 |

210 |

6 |

18 |

8 |

5.21 |

|

150 |

168.0 |

285 |

174 |

24 |

240 |

6 |

22 |

8 |

6.89 |

|

|

153.0 - 156.0 |

285 |

164 |

24 |

240 |

6 |

22 |

8 |

6.89 |

|

200 |

219.1 |

340 |

226 |

26 |

295 |

6 |

22 |

12 |

9.31 |

|

250 |

273.0 |

405 |

281 |

29 |

355 |

8 |

26 |

12 |

13.50 |

|

300 |

323.9 |

460 |

333 |

32 |

410 |

8 |

26 |

12 |

18.00 |

|

350 |

355.6 |

520 |

365 |

35 |

470 |

8 |

26 |

16 |

27.00 |

|

400 |

406.4 |

580 |

416 |

38 |

525 |

8 |

30 |

16 |

34.60 |

|

450 |

457.0 |

640 |

467 |

42 |

585 |

8 |

30 |

20 |

44.60 |

|

500 |

508.0 |

715 |

519 |

46 |

650 |

8 |

33 |

20 |

62.00 |

PN25

|

DN |

Pipe OD |

D |

B2 |

C1 |

K |

E |

L |

Qtty. |

Weight |

|

200 |

219.1 |

360 |

226 |

32 |

310 |

6 |

26 |

12 |

13.80 |

|

250 |

273.0 |

425 |

281 |

35 |

370 |

8 |

30 |

12 |

19.40 |

|

300 |

323.9 |

485 |

333 |

38 |

430 |

8 |

30 |

16 |

25.50 |

PN40

|

DN |

Pipe OD |

D |

B2 |

C1 |

K |

E |

L |

Qtty. |

Weight |

|

10 |

17.2 |

90 |

21 |

14 |

60 |

3 |

14 |

4 |

0.60 |

|

15 |

21.3 |

95 |

25 |

14 |

65 |

3 |

14 |

4 |

0.65 |

|

20 |

26.9 |

105 |

31 |

16 |

75 |

4 |

14 |

4 |

0.91 |

|

25 |

33.7 |

115 |

38 |

16 |

85 |

4 |

14 |

4 |

1.08 |

|

32 |

42.4 |

140 |

47 |

18 |

100 |

5 |

18 |

4 |

1.77 |

|

40 |

48.3 |

150 |

53 |

18 |

110 |

5 |

18 |

4 |

2.02 |

|

|

40.0 - 44.5 |

150 |

50 |

18 |

110 |

5 |

18 |

4 |

2.02 |

|

50 |

60.3 |

165 |

65 |

20 |

125 |

5 |

18 |

4 |

2.65 |

|

65 |

76.1 |

185 |

81 |

22 |

145 |

6 |

18 |

8 |

3.36 |

|

80 |

88.9 |

200 |

94 |

24 |

160 |

6 |

18 |

8 |

4.18 |

|

100 |

114.3 |

235 |

120 |

26 |

190 |

6 |

22 |

8 |

5.87 |

|

125 |

139.7 |

270 |

145 |

28 |

220 |

6 |

26 |

8 |

7.95 |

|

150 |

168.3 |

300 |

174 |

30 |

250 |

6 |

26 |

8 |

9.97 |

Xinhang Special Material Co., Ltd. Hangzhou Branch is famous China Precision Forging SS Lap Joint Flange With Stub Ends suppliers and OEM/ODM Precision Forging SS Lap Joint Flange With Stub Ends manufacturers, founded in 2007 and moved to Longyou Economic Development Zone, Zhejiang Province, in 2022. It covers an area of 130,000 square meters, more than 30 production lines, 300 workers, 20 R&D people, 30 inspection people and an annual output of 50,000 tons.

It has passed ISO9001:2008 quality management system, PED 97/23/EC EU Pressure Equipment Directive certification, China Special Equipment Manufacturing License (Pressure Tube) TS certification, ASME certification, provincial enterprise standardization management system, ISO14000:2004 environment management system, cleaner production (green enterprise), and a series of certifications, as well as China Classification Society (CCS), American Bureau of Shipping (ABS), British Register of Shipping (LR), Deutsche Veritas (GL), Bureau Veritas Society (BV), Det Norske Veritas (DNV), and Korean Register of Shipping (KR) factory certification.

The main products include stainless steel pipes, pipe fittings, flanges, valves, etc., which are widely used in petroleum, chemical industry, nuclear industry, smelting, shipbuilding, pharmaceuticals, food, water conservancy, electric power, new energy, mechanical equipment, and other fields. The company adheres to the corporate tenet of "quality for survival, reputation for development" and wholeheartedly serves every customer to create a win-win situation.

Bottom line: how to weld stainless steel pipe without sugar and leaks For most stainless steel pipe work, the most reliable path to clean, corrosion-resistant, leak-tight welds is: GTAW (TIG) root wi...

View MoreDirect answer: what a “stainless steel pipe pressure rating” really means A stainless steel pipe does not have one universal pressure rating. The correct “stainless steel pipe pressure rating” is the...

View MoreIn our shop, bending stainless steel pipe is one of those operations that looks simple but punishes shortcuts. Stainless work-hardens, it springs back, and thin-wall sections will oval or wrinkle if t...

View MoreWe'll never share your email address and you

can opt out at any time, we promise.